Sensor & camera solutions

Xenics is a global provider of infrared sensors, cores and cameras. The product range includes infrared image sensors, such as InGaAs SWIR sensors and other specialty sensor types, as well as infrared camera systems. Xenics sells cameras operating in the short-wave, mid-wave and long-wave infrared, in both line scan and area scan varieties. The sensor and cameras are used in a wide array of applications, such as machine vision, science, transportation, security, space, medical, and process monitoring.

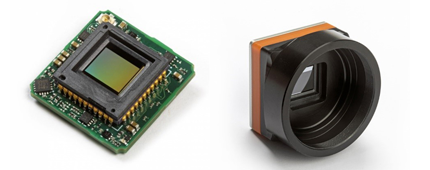

I’ve been working as a consultant in the test, measurement and characterization department. The engineers test almost all aspects of the devices developed and manufactured by Xenics. The different types of tests range from ROIC-level characterization of sensors, to performance measurements of the camera platforms, as well as testing firmware and software. My work has been focused on characterizing a new long-wave infrared camera platform that launched this summer. The new OEM module product, named Dione, is optimized for small size, weight and power, and has a VGA image resolution.

Characterizing the performance is crucial for a device where the optimization for certain properties introduces important trade-offs. Firstly, my tasks include taking measurements of traditional (thermal camera) properties such as NETD, dynamic range, power and timing requirements, and the temperature dependency of those properties. Secondly, the Dione module requires an image processing algorithm to correct for the different temperatures of the sensor because it is a shutterless, uncooled microbolometer device. I also worked on the optimization of parameters for a shutterless non-uniformity correction algorithm that fully runs on the module.

Because of the close collaboration between the test team and other engineering teams, we could identify problems quickly and implement the right fixes.

Part of my tasks includes automatizing the characterization tests and production procedures, so they can be repeated more efficiently in the future. As we’re looking to expand the Dione platform to other resolutions, including SXGA, this saves the company considerable time. Automating tests and procedures is part of the continuing progress towards better test repeatability and production consistency.

As a result of the close collaboration between test team and other engineering teams, problems during development were identified quickly and the right fixes were implemented. The Dione module launched earlier this summer and customer reactions have been great.

Any questions on this post? Submit them below and we’ll get back to you soon!

- Compentences: Electronics

- Client: Xenics