Production optimization in 3D & 2D

Sedac-Meral Group is the European leader in the manufacturing of metal mechanisms for sofa and convertible beds. Thanks to a 30-year experience in the sofa business, Sedac-Meral enjoys strong brand recognition and maintains a reputation for technical know-how. In fact, Sedac-Meral has become the name of reference in the convertible sofa sector.

Sedac-Mecobel, mother company of Sedac-Meral, is located in Wevelgem and occupies a site of 45.000 m2. In the west of France, Sedac-Meral occupies 31.000 m2.

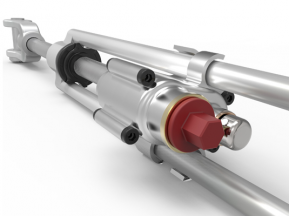

Sedac-Meral deals essentially with metal tubes and metal sheet parts. The ‘know-how’ regarding bending, punching, cutting, rejuvenating and other chipless metal and aluminum forming techniques for pipes, is therefore obvious. The machines are fully automated and allows Sedac to produce more than 6.000 mechanisms daily. Sedac has its own engineering department which allows to constantly improve productivity.

Djurre Vanlede, on-site mechanical designer at Verhaert Consulting, is part of the R&D department which focuses on developing new mechanisms and products. The mechanical linkage systems look simple at first sight, but the parts of such a structure undergo a lot of internal stresses and deformations.

My main task was the implementation of product and production improvements in 3D and 2D.

A lot of testing and optimization is required to obtain a good functioning system that can resist the daily use of opening and closing the structure. There’s also a constant optimization of existing products to improve production of the mechanisms.

We need to put great focus on the cheap production of our products to compete with other companies. That’s why every part is well studied and the production needs to be automated as much as possible.

When Djurre started working at Sedac, his main task was the implementation of product and production improvements in 3D and 2D. It gave him the chance to get to know the different products and to get familiar with the rather specific market. Now it’s a challenge to improve existing mechanisms and to help develop new sofabedsystems.

Any questions on this post? Submit them below and we’ll get back to you soon!